Ultimate Guide to DTF Printing Coatesville: Affordable, High-Quality Custom Apparel

Introduction to DTF Printing: Affordable DTF Printing in Coatesville

What is DTF Printing?

DTF (Direct to Film) printing is revolutionizing the world of custom apparel. Unlike traditional methods, this process involves printing a design onto a specialized film and then transferring it onto fabric using heat and pressure. If you’ve searched for “custom printing near me,” you’re likely looking for a fast, high-quality, and affordable way to personalize garments. Print Habit are experts in DTF printing in Coatesville. Print Habit offers all of that and more with dtf printing technology that stands out for its quality and efficiency, making it a top choice for custom projects.

Why is DTF Growing in Popularity?

Customers love DTF printing because it’s versatile, quick, and produces vibrant prints that last. Whether you’re a small business owner, a fashion enthusiast, or planning an event, DTF printing provides a practical solution that doesn’t compromise on quality.

How Does DTF Work?

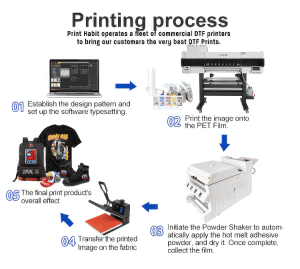

Step-by-Step Breakdown of the DTF Printing Process

The DTF printing process involves several precise steps:

The advantages of dtf printing include its ability to produce intricate designs and vibrant colors, making it a favored choice among businesses and individuals alike. This method ensures longevity and customer satisfaction, solidifying its reputation in the printing industry.

Design Creation – Artwork is prepared digitally, ensuring it’s compatible with DTF printing specifications.

Film Printing – The design is printed onto a PET film using specialized DTF ink.

Powder Coating – A fine adhesive powder is applied to the printed film.

Curing – The film is gently heated to melt the powder into the ink.

Heat Transfer – Using a heat press, the design is transferred onto the fabric.

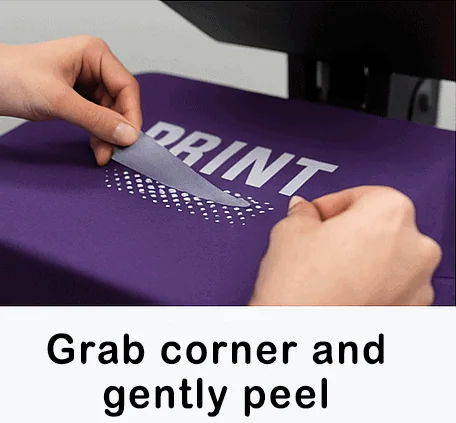

Peel & Finish – Once cooled, the film is peeled off, leaving the design bonded to the fabric.

Required Equipment and Materials

DTF Printer & Shaker Oven

PET Transfer Film

DTF Ink (white and CMYK)

Hot Melt Adhesive Powder

Heat Press Machine

Print Habit maintains a fleet of commercial DTF printers to bring our customers the very best DTF Prints. The DTF printing process involves specialized films, hot melt powder, and heat transfer equipment—all of which work together to produce vibrant, durable prints. This modern method has evolved quickly in recent years, earning recognition across the apparel industry for its versatility. (For additional industry context, see this technical overview of Direct-to-Film technology.)

Printing vs. Other Methods

DTF vs. Screen Printing

While screen printing is excellent for bulk orders, DTF shines with its detail and cost-effectiveness for smaller runs. No screens to burn or messy setup—just high-quality prints with minimal effort. You can read more about DTF vs screen printing in our guide.

DTF vs. DTG (Direct-to-Garment)

DTG requires cotton fabrics and doesn’t adhere well to synthetics. DTF, on the other hand, sticks to cotton, polyester, blends, and more. It’s flexible and more adaptable to various materials.

The Advantages of DTF Printing & Why This Method Stands Out

-

No pre-treatment needed

-

Sharp, full-color graphics

-

Ideal for both light and dark fabrics

-

Perfect for on-demand orders

Key Benefits

Cost-Effectiveness

DTF printing is incredibly affordable, especially for small to medium orders. Unlike traditional methods that demand bulk runs, DTF is great for low-quantity, custom jobs.

Vibrant Colors and Versatility

DTF prints pop with color. The ink and powder combo ensures designs look sharp and colorful, even on dark garments.

Durable Prints That Last

DTF transfers withstand multiple washes without cracking or fading. When done right, the prints can last just as long—or longer—than traditional screen prints.

Best Use Cases

Ideal Fabrics and Garments

-

Cotton

-

Polyester

-

Cotton-poly blends

-

Canvas bags

-

Hoodies, T-shirts, Jerseys, and more

Perfect for Small Businesses and Events

Need branded T-shirts for your startup or event merch for a fundraiser? DTF makes it easy to print custom apparel without breaking the bank.

Exploring Custom Printing Near Me

Local Solutions for Custom Apparel

If you’re based in or near Coatesville, you’re in luck. Print Habit offers quick turnarounds and expert service, ensuring your custom DTF printing needs are met with professionalism.

What to Look for in a Custom DTF Provider

-

Experience and reviews

-

Quality of transfers

-

Speed of service

-

Transparent pricing

-

Custom design support

Behind the Scenes: The DTF Printing Process

Film Printing

Designs are printed in reverse onto PET film using eco-friendly ink.

Powder Application

A fine adhesive powder is evenly spread over the wet ink.

Heat Pressing

The film is pressed onto the fabric using a heat press at ~325°F. The film is then peeled off, leaving a stunning, durable print.

Cost Considerations

Pricing Breakdown

Pricing can vary depending on:

| Factor | Impact |

|---|---|

| Quantity | More prints = Lower cost per unit |

| Size of Print | Larger prints use more ink and film |

| Number of Colors | DTF handles all colors with ease, no extra charge |

| Turnaround Time | Rush jobs may carry extra fees |

Cost vs. Value Comparison

For high-detail, low-run, and quick turnaround needs, DTF printing offers unbeatable value.

How to Order Custom Transfers

Steps to Place an Order

-

Upload your design file

-

Choose garment type and size

-

Select quantity and shipping options

-

Approve digital proof

-

Receive your printed items or transfers

Design File Guidelines

-

Use vector formats (AI, EPS, or high-res PNG)

-

300 DPI minimum

-

Transparent backgrounds for best results

Turnaround Times

Print Habit, a local DTF printing service in Coatesville ships or delivers in 3–5 business days, with rush options available. Print Habit custom DTF transfers have same day, 3-day and 5-day delivery or shipping options and processing tie discounts available.

Final Thoughts on Printing Coatesville

DTF printing Coatesville is not just a trend—it’s the future of custom apparel. Offering vibrant colors, unmatched versatility, and unbeatable value, it’s a go-to for anyone needing fast, reliable custom prints. Whether you’re exploring how the DTF printing process works or searching for “custom DTF printing near me,” this method delivers on all fronts. Ready to print? Check out our custom DTF transfers and explore our DTF printing service today!

Frequently Asked Questions (FAQs)

Is DTF better than vinyl or screen printing?

It definitely can be depending on your situation. DTF combines the flexibility of vinyl with the durability of screen printing, without the mess or setup. It offers full color vibrant prints without screen setup or charges. Screen printing is often charged by number of colors. There are no such charges or setup with DTF printing.

Can I wash DTF printed garments often?

Absolutely! DTF prints can handle 50+ washes without significant fading. When properly cared for, DTF can last much longer. In general, care instruction require cold wash, turning inside out, and warm ironing.

How long do DTF prints last?

When properly applied and cared for, DTF prints can last for years.

Where can I get custom DTF printing near me?

If you’re in Coatesville, Print Habit offers DTF printing services with fast turnaround and expert results. Print Habit also serves Downingtown, Exton, Parkesburg, and Honey Brook for fast DTF printing and free local delivery for qualifying orders..

What types of clothing can DTF be applied to?

DTF works on T-shirts, hoodies, jackets, tote bags, and even hats. DTF prints can even be applied to some non-fabric items.

Can I provide my own artwork for DTF transfers?

Yes! Absolutely! Just ensure it meets the resolution and format guidelines for best results. You can read our print ready artwork guide here. If you need help, just give us a call or text – (610) 508-9993

How to Apply Print Habit Custom DTF Transfers

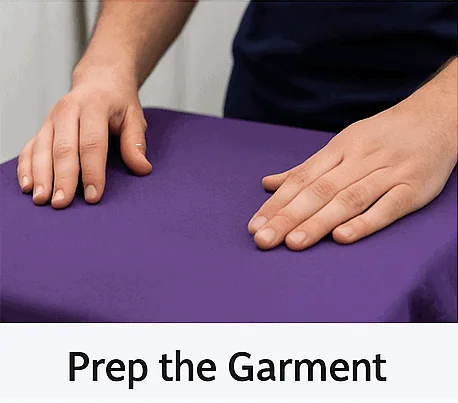

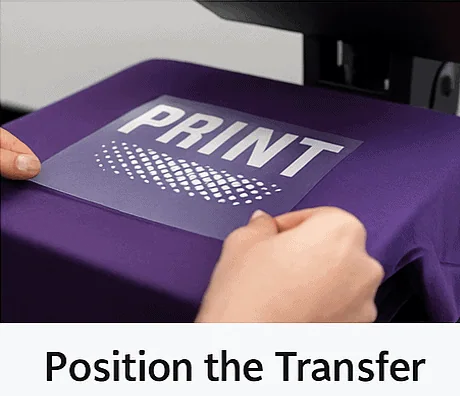

Learn how to apply custom DTF transfers for professional results using a heat press. Follow these simple steps to ensure your design looks great and lasts wash after wash.

Required Tools:

Materials Needed?

Steps To Press DTF Transfers Onto Garment